Impact of Improper Battery Disposal

Discarded batteries leach heavy metals such as lead, mercury, cadmium, and nickel into soil and groundwater, leading to bioaccumulation in plants and animals, and eventually entering the human food chain.

Corrosive acids and electrolytes within batteries can alter pH levels in landfills, disrupting microbial ecosystems responsible for organic waste decomposition.

Lithium-ion batteries, when crushed or punctured, can experience internal short circuits, sparking fires that are difficult to extinguish and emit toxic fumes like hydrogen fluoride.

Inadequate sorting at waste facilities causes batteries to mix with general waste streams, increasing the risk of fires at recycling plants and putting workers at risk.

According to the EPA, less than 5% of portable batteries are recycled in the U.S., resulting in millions of tons of e-waste accumulating worldwide each year.

Environmental Harm

Toxic leakage contaminates water bodies, harming aquatic life and reducing biodiversity.

Health Risks

Heavy metal poisoning can cause neurological damage, kidney disease, and developmental issues in children.

Resource Depletion

Discarding batteries wastes valuable materials like cobalt and nickel, driving demand for invasive mining.

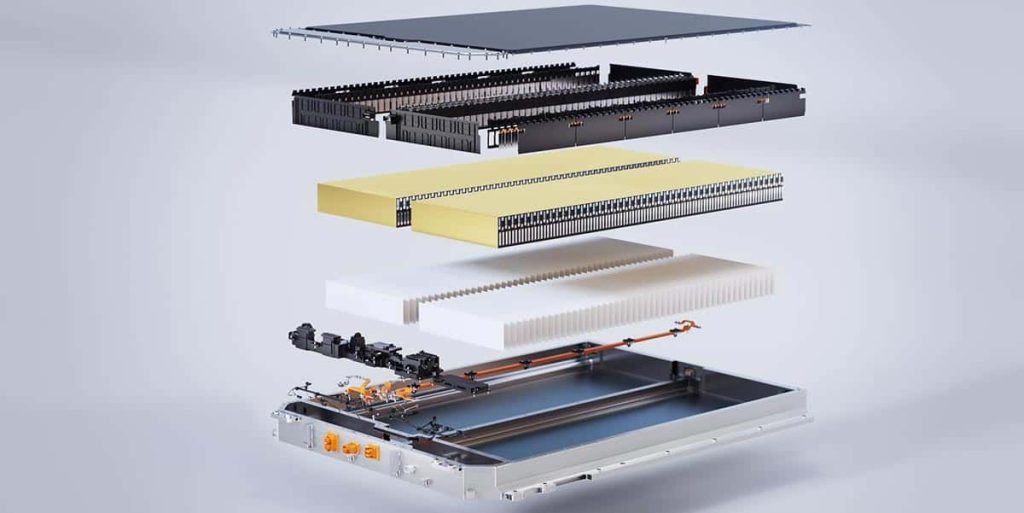

Solution: Brick Batteries

Brick batteries are standardized, stackable modules designed for a circular economy. Each module can be easily removed, serviced, or replaced, eliminating the need to discard entire battery packs.

The modular design simplifies logistics: recovered bricks can be retested and redistributed, reducing manufacturing footprints by up to 30% compared to custom pack assemblies.

These batteries use eco-friendly electrode materials with reduced cobalt content and water-based electrolytes, lowering toxicity and improving end-of-life recyclability.

Pilot programs in Europe have demonstrated that brick battery systems can achieve 90% material recovery, cutting landfill-bound e-waste by half in participating regions.

Adoption challenges include standard-setting across manufacturers and developing reverse-logistics networks for module collection—initiatives that are already underway through industry consortia.